Products

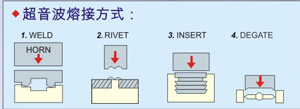

- ULTRASONIC PLASTIC WELDING MACHINE

- ULTRASONIC METAL WELDING MACHINE

- SPECIAL WELDING EQUIPMENT

- VIBRATION WELDING MACHINE

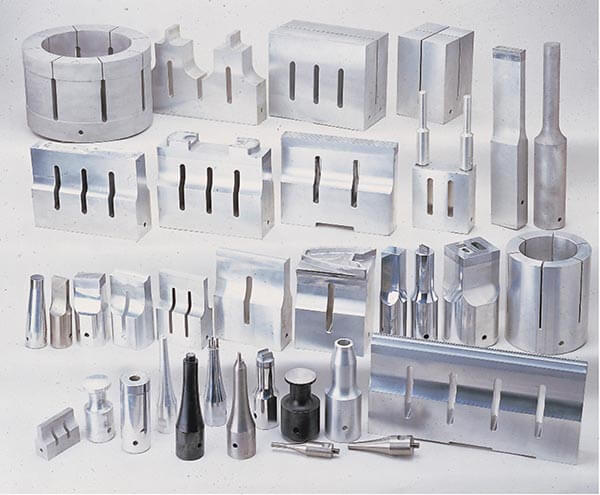

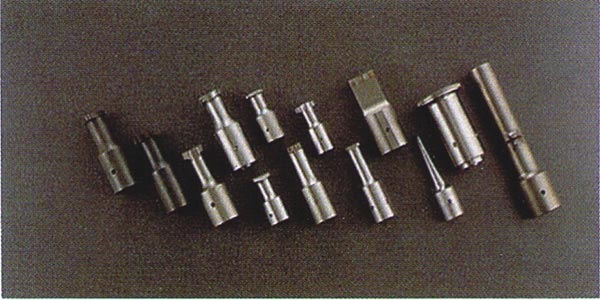

- ULTRASONIC COMPONENTS

- CUSTOMIZED EQUIPMENT

- ULTRASONIC TEXTILE PROCESSING EQUIPMENT

- SEMICONDUCTOR PRECISION CLEANING MACHINE

- MEDICAL / HEALTHCARE

- AESTHETIC PRODUCTS

- ENVIRONMENT HUMIDIFIER

Home > Products > ULTRASONIC PLASTIC WELDING MACHINE > KWD SERIES

KWD SERIES

Specification

| MODE | KWD1230 | KWD1235 | KWD1230-N | KWD1235-N | |

| SPEC | OUTPUT | 1200W | |||

| FREQUENCY | 30KHz | 35KHz | 30KHz | 35KHz | |

| LINE SOURCE | AC220V ,15A, 50/60HZ,single-phase | ||||

POWER SYSTEM |

ULTRASONIC SYSTEM |

|

|||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

CONTROL SYSTEM |

|

|

|||

|

|

||||

|

|

||||

|

|

||||

|

|

||||

|

|||||

|

|||||

|

|||||

| MECHANICAL SYSTEM |

|

||||

|

|||||

|

|||||

|

|||||

| GENERATOR DIMENSION | 525×156×271㎜(L×W×H) | 405×145×286㎜(L×W×H) | |||

| GENERATOR WEIGHT | 11Kgs | 8Kgs | |||

| MACHINE DIMDENSION | 475×300×770~1030㎜(L×W×H) | 475×300(+240 ~380)×770~1030㎜(L×W×H) | |||

| MACHINE WEIGHT | 40Kgs | 45Kgs | |||

Other 1

Applicable material: ABS,PS,PP,PVC,Acrylic,Nylon,PC,PE........

Other 2

Trade Information