KWG2620-EW

Ultrasonic Metal Welding Machine

Description

- Ultrasonic metal welding, generally for the fusion of low melting point metal materials such as copper, aluminum, etc.

- Taking the ultrasonic welding metal plate as an example, the two metal plates are overlapped and placed on the base, and the ultrasonic welding head is pressed against the coincident metal plate with appropriate pressure, and a lateral vibration of 20,000 to 40,000 times per second is applied. The two metal plate joints are subjected to high frequency vibration friction and welded.

In this welding mode, the solvent is not required, and the welding portion does not need to pass current and heat, and is close to the cold joint, and the intermetallic compound is less likely to occur, and the structure changes little. The welding feature is that the deformation of the joint is less, the material is not melted, and the thermal influence of the material is not significantly changed. The fragile cast structure or the intermetallic compound can be obtained, and the fusion of the foil and the small joint can be achieved without strong resistance welding. Long foil can be applied by roller type continuous welding.

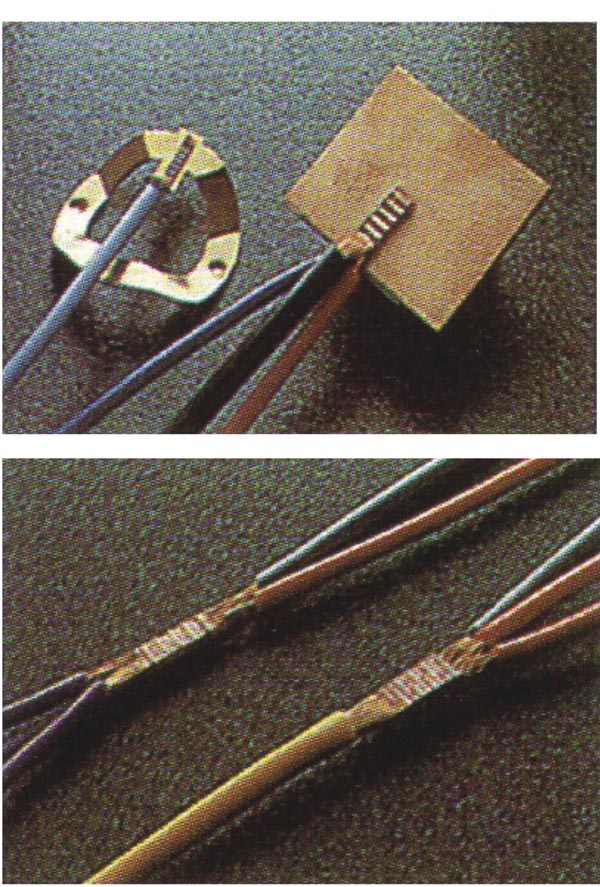

- KWG0935 model can be applied to lithium battery copper aluminum foil and aluminum nickel sheet welding, copper aluminum foil spot welding, capacitor copper aluminum foil spot welding, etc.

- KWG2020 model can be applied to lithium battery aluminum shell and aluminum nickel sheet welding, wire and terminal welding, wire butt welding, wire and metal plate welding, metal plate spot welding, etc........

- Ultrasonic metal welding, generally for the fusion of low melting point metal materials such as copper, aluminum, etc.

- Taking the ultrasonic welding metal plate as an example, the two metal plates are overlapped and placed on the base, and the ultrasonic welding head is pressed against the coincident metal plate with appropriate pressure, and a lateral vibration of 20,000 to 40,000 times per second is applied. The two metal plate joints are subjected to high frequency vibration friction and welded. In this welding mode, the solvent is not required, and the welding portion does not need to pass current and heat, and is close to the cold joint, and the intermetallic compound is less likely to occur, and the structure changes little. The welding feature is that the deformation of the joint is less, the material is not melted, and the thermal influence of the material is not significantly changed. The fragile cast structure or the intermetallic compound can be obtained, and the fusion of the foil and the small joint can be achieved without strong resistance welding. Long foil can be applied by roller type continuous welding.

- KWG0935 model can be applied to lithium battery copper aluminum foil and aluminum nickel sheet welding, copper aluminum foil spot welding, capacitor copper aluminum foil spot welding, etc.

- KWG2020 model can be applied to lithium battery aluminum shell and aluminum nickel sheet welding, wire and terminal welding, wire butt welding, wire and metal plate welding, metal plate spot welding, etc........